Corrosion Scales on Galvanized Service Lines and Premise Plumbing

Galvanized piping was the dominant material used for internal plumbing in U.S. housing for many years. It is still presnet both as original plumbing and random replacement fittings in large numbers of homes and schools. Galvanized pipes are associated with serious problems from two sources: failure through excessive corrosion and the associatoin of lead with the iron scales in many localities.

Galvanized was the plumbing material of choice in homes built before the 2nd World War. It began to be replaced by copper from the 1950s owing to lower installation costs and superior corrosion resistance for Cu. Galvanized continued to be widely used, however, in repairs, with galvanized fittings commonly being used instead of much more expensive brass fittings.

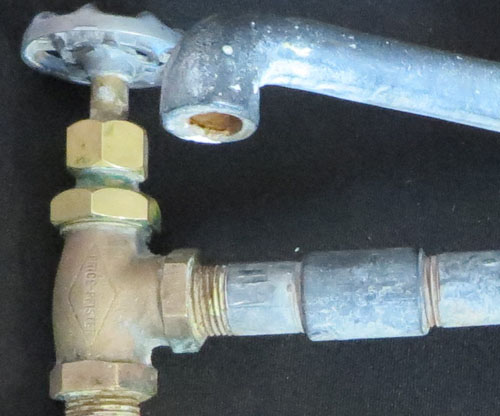

A history of service branches. Galvanized fell out of favor in the 1960s, but countless examples still remain in place.

Mixed brass and galvanized (Utility 5).

Mixing metal types inevitably occurs when a galvanized line leads to a brass faucet. However, many copper systems will have some of their brass fittings replaced by galvanized. Even one or two galvanized fittings in a water line can affect water quality.

It is also likely that accelerated corrosion will occur at the junction of the dissimilar metals, as shown by the brass-to-galvanized connection below..

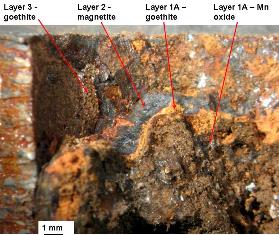

Some examples of iron corrosion scales on galvanized components

(click on an image for a larger version)

U